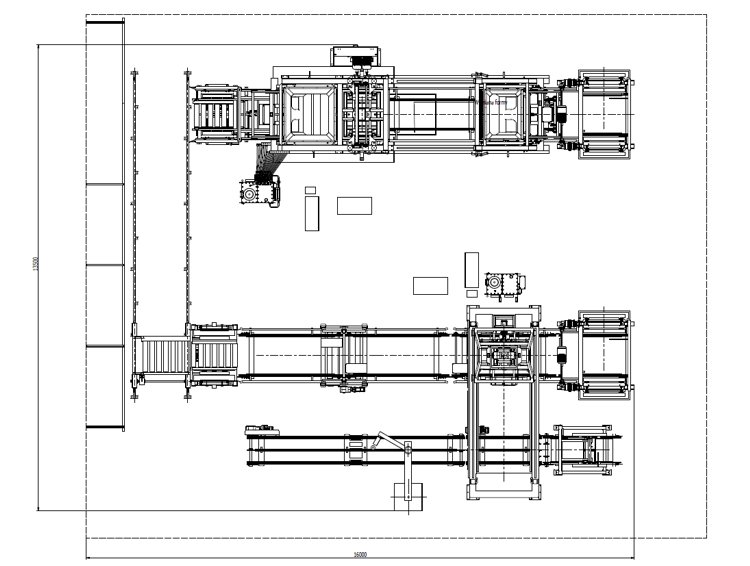

The line consists of a set of devices that enable the entire technological process to be carried out, from the manufacture of components, through their drying, to the preparation of cargo ready for trade.

The compact design of the lines and the use of multi-level shelf racks allow for optimal surface management.

The integral part of the line is the TYTAN 3 Stationary Forming Machine – a modern machine with a large molding area that enables the production of a wide range of prefabricated components high performance.

The molding of the elements takes place on production pallets measuring 1400x1100x50 mm.

Main line components:

The control system allows for complete management of molding parameters (saving, correcting, deleting, selecting a set from a list) and ensures the production and packaging process. The fast driver, which is very resistant to temperature changes, ensures software safety and ensures rapid response to machine changes.

The line is also based on TYTAN 3 machine. Depending on your preference or local conditions, the line may be open, semi open or closed

The line consists of the following components:

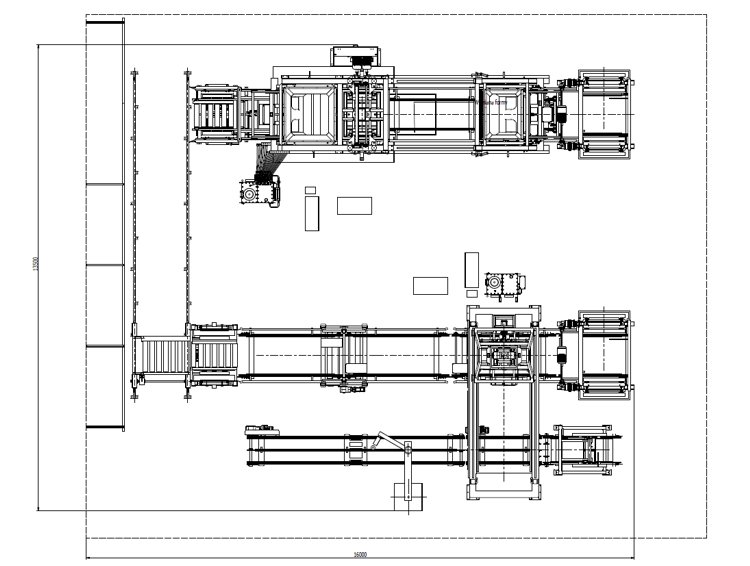

The line consists of a set of devices that enable the entire technological process to be carried out, from the manufacture of components, through their drying, to the preparation of cargo ready for trade.

The compact design of the lines and the use of multi-level shelf racks allow for optimal surface management.

The integral part of the line is the TYTAN 3 Stationary Forming Machine – a modern machine with a large molding area that enables the production of a wide range of prefabricated components high performance.

The molding of the elements takes place on production pallets measuring 1400x1100x50 mm.

Main line components:

The control system allows for complete management of molding parameters (saving, correcting, deleting, selecting a set from a list) and ensures the production and packaging process. The fast driver, which is very resistant to temperature changes, ensures software safety and ensures rapid response to machine changes.

The line is also based on TYTAN 3 machine. Depending on your preference or local conditions, the line may be open, semi open or closed

The line consists of the following components: