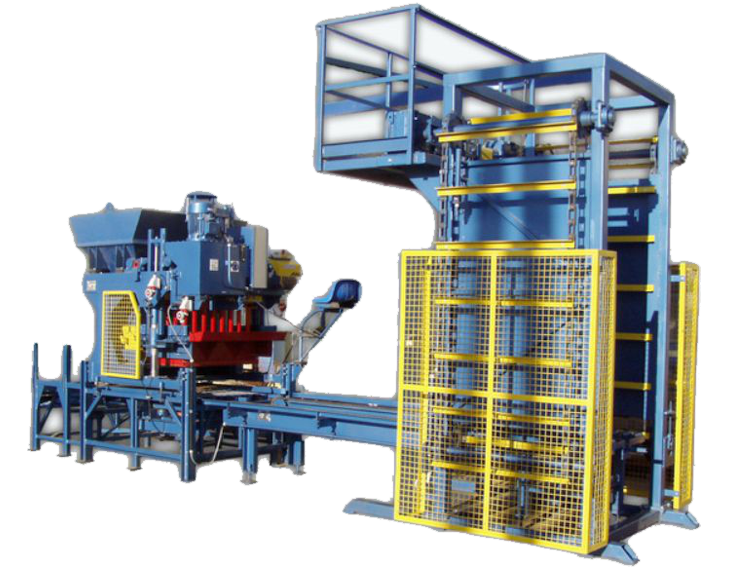

The stationary hydraulic MINI-MAX concrete block machine is designed for the production of small-size construction elements, such as: structural-wall tiles, structural-floor tiles, formwork blocks, chimney blocks, ventilating blocks, foundation blocks lawn edges, planter elements, openwork elements and so on.

The machine operates in a stationary mode. It is equipped with the vibrating table with the pallet feeder, and with a steel construction enabling the adjustment of mould height and fixing the concrete block machine to the ground. The way the mould and the punches are fixed prevents their swinging and transferring the vibrations onto the main body of the machine. Isolating the vibrations from the charging hopper protects the mass from unwanted vibration.

There are 4 vibrators fixed in the machine: two on the mould and two on the punches. Punches are equipped with mechanic blocking system which allows to achieve a constant production output. The concrete block machine is operated manually by means of proportional manipulator.

Machine design makes it easy to exchange the mould, thanks to which it is possible to adjust the production to the changes occurring on the market.

Chain conveyor serves for collecting the products from the machine. Next, pallets with products are piled up thanks to the use of the stacking device. Transport and stabilizing of products is done with the use of special shelves adjusted to be handled by the fork-lift truck.

| Machine operation with the receiving line: | 2 person |

| Cycle time: | 30/40 sec. |

| Maximum length of the mould: | 600 mm |

| Maximum width of the mould: | 1080 mm |

| Maximum height of the mould: | 300 mm |

| Minimum height of the mould: | 120 mm |

| Capacity of the batch drawer: | 120 l |

| Capacity of the batch basket: | 0,75 m3 |

| Capacity of oil container: | 90 l |

| Installed power: | |

| – of the machine: | 7,5 kW |

| – receiving line: | 0,75 kW |

| – device piling: | 4,0 kW |

| Height of the table: | 1200 x 650 x 40 mm |

| Efficiency: | 2500-5000* items/8h |

| Maximum size (height x width length): | |

| – of the machine: | 3830 x 1900 x2850 mm |

| – of the machine with the receiving line | 7440 x 2150 x 3980 mm |

* depending on the size of moulded elements

The stationary hydraulic MINI-MAX concrete block machine is designed for the production of small-size construction elements, such as: structural-wall tiles, structural-floor tiles, formwork blocks, chimney blocks, ventilating blocks, foundation blocks lawn edges, planter elements, openwork elements and so on.

The machine operates in a stationary mode. It is equipped with the vibrating table with the pallet feeder, and with a steel construction enabling the adjustment of mould height and fixing the concrete block machine to the ground. The way the mould and the punches are fixed prevents their swinging and transferring the vibrations onto the main body of the machine. Isolating the vibrations from the charging hopper protects the mass from unwanted vibration.

There are 4 vibrators fixed in the machine: two on the mould and two on the punches. Punches are equipped with mechanic blocking system which allows to achieve a constant production output. The concrete block machine is operated manually by means of proportional manipulator.

Machine design makes it easy to exchange the mould, thanks to which it is possible to adjust the production to the changes occurring on the market.

Chain conveyor serves for collecting the products from the machine. Next, pallets with products are piled up thanks to the use of the stacking device. Transport and stabilizing of products is done with the use of special shelves adjusted to be handled by the fork-lift truck.

| Machine operation with the receiving line: | 2 person |

| Cycle time: | 30/40 sec. |

| Maximum length of the mould: | 600 mm |

| Maximum width of the mould: | 1080 mm |

| Maximum height of the mould: | 300 mm |

| Minimum height of the mould: | 120 mm |

| Capacity of the batch drawer: | 120 l |

| Capacity of the batch basket: | 0,75 m3 |

| Capacity of oil container: | 90 l |

| Installed power: | |

| – of the machine: | 7,5 kW |

| – receiving line: | 0,75 kW |

| – device piling: | 4,0 kW |

| Height of the table: | 1200 x 650 x 40 mm |

| Efficiency: | 2500-5000* items/8h |

| Maximum size (height x width length): | |

| – of the machine: | 3830 x 1900 x2850 mm |

| – of the machine with the receiving line | 7440 x 2150 x 3980 mm |

* depending on the size of moulded elements