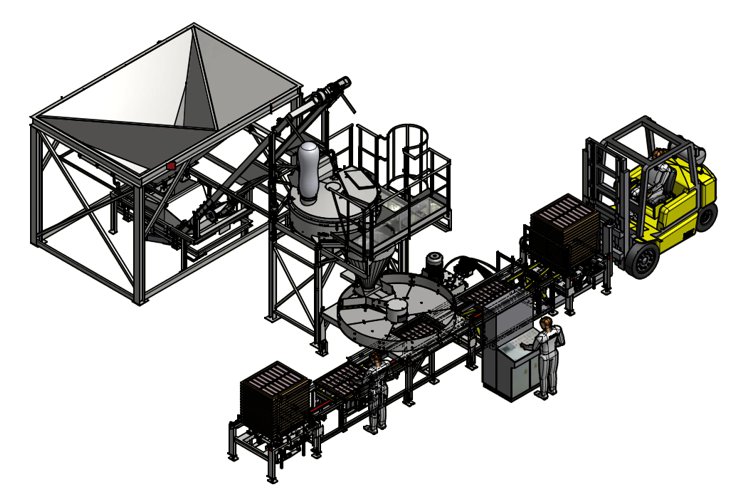

The line is designed to produce decorative tile tiles by vibration method.

The line includes:

- concrete mixer with a capacity of 375 l with supporting structure

- Tank for 3 fractions of aggregate – capacity for individual fractions: 4m 3 + 2m3 + 2m3

- hopper with aggregate weighing function

- Flow rate of water to the mixer

- cement storage and dispensing system – silo, auger, scales

- concrete basket with swivel bar

- dispenser that allows the precise molding of the molds into different patterns / sizes of stone by the use of removable molds that match the size of the molds

- magazine tops

- mold washer

- weight distribution station

- vibrating table

- stacking device

- pallet transporter, which provides pallet circulation from the pallet store, through the mold lubrication station, mass dispensing, mass spreading to the stacking station of the wet product

- control panel for control of mass production and batching process and pallet circulation in line