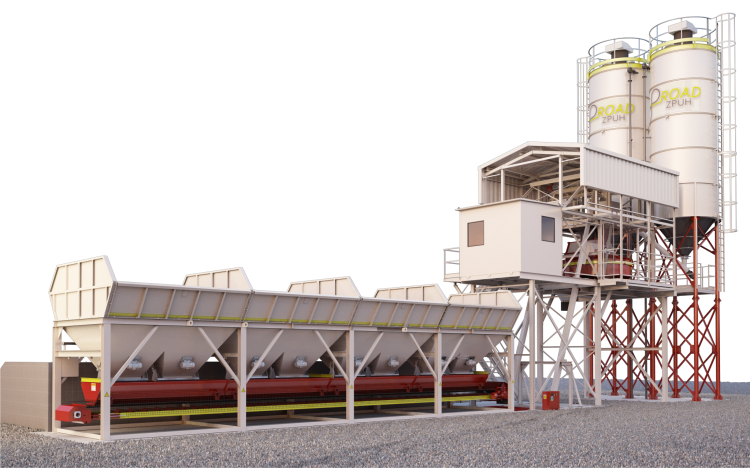

- The use of state-of-the-art mixers (trurbine, planetary or twin-shaft), ensuring high quality of mixing and high efficiency, designed for producing all kinds of concrete mixes, including dry mixes for the production of prefabricated elements, as well as for producing service concrete mix.

- The use of replaceable flooring and panelling of the mixers, made of materials of high hardness and resistance to abrasion, ensuring long lifespan – ceramics (kalocer); hardox, cast iron reinforced by nickel.

- Microwave measurement of moisture of concrete mix with the use of HYDRONIX probes, integrated with the control system, ensuring automatic correction of the recipe, and consequently the intended consistency of the concrete mix.

- Tensometric weighing systems of high precision of measurement, ensuring accuracy of weighing that is compliant with the requirements of the binding norms.

- The possibility of re-use of recycling components – knots cooperating with recycling devices what ensures a closed production cycle and, as a consequence, protection of natural environment.

- The use of heavy duty filters for ventilation of the Silotop silo with the surface of 24.5m2 – ensuring almost dust-free production of concrete.

- Securing concrete silos against a sudden increase in pressure or subatmospheric pressure inside the silo, through spring release valves.

- The systems indicating the level of concrete in silos and the systems of refuelling control, constituting a protection against overflowing of the silos.

- The control system, developed on the basis of the state-of-the-art Mitsubishi industrial driver FX series, cooperating with the operator’s panel, marked by the full control of the production course, graphical illustration of the condition of the line; expanded system of production reporting and the full archiving of data, local or/and network planning and production management.

Our concrete knots ensure:

- achieving high efficiency of production output, with the simultaneous eliminating of the physical effort of service personnel and minimizing of human mistakes

- fulfilment of process requirements for a given class of concrete and the completion of the production process of concrete mix in accordance with the recipe

- optimum consumption of water and other raw materials for the production thanks to the precise dispensing of components and the correction of the recipe basing on the measurement of moisture and the possibility of re-use of the materials

- full automation and visualization of the production process

- full registration of the production and printing of transport documents, pursuant to the binding norms

- the possibility of optimum development of the surface area thanks to the configuration of the line adjusted to site conditions

- fulfilment of the workplace safety conditions required by law thanks to the application of: line safety sensors, protection of service flaps of the mixer, the protection against paying out a rope, power and drives control, protection against overloading of scales, the control of the condition of all sensors, permanent shields – mesh, balustrade, guard rail

- fulfilment of the environmental requirements thanks to solutions limiting the negative impact on the environment