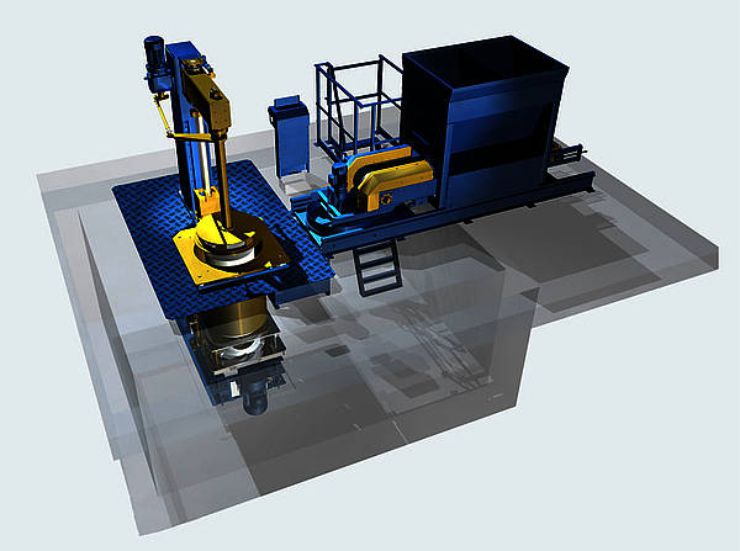

The hydraulic stationary RING-600 machine is designed for the production of concrete pipes, round or with a flange, of the core diameter from fi 300 to fi 600.

The machine comprises:

A mechanical concrete mass fill, streamlining the production process, and a scraper ensures even distribution of the concrete mass in the mold. Hydraulic top ring pressure ensures high quality connections.

The machine construction ensures quick and easy exchange of molds.

The machine uses a special axial vibrator construction, which allows for a very good final product.

Control is done manually using a proportional hydraulic manifold.

Ready-made items are seasoned on steel bottom sleepers. The hand truck is used to haul items to the place of seasoning.

| Operation of the machine: | 1 person |

| Minimum height of the mould: | 1000 mm |

| Maximum core diameter: | 600 mm |

| Minimum core diameter: | 300 mm |

| Maximum the diameter of the coat: | 800 mm |

| Capacity of the batch basket: | 1,2 m3 |

| Capacity of oil container: | 225 l |

| Installed power: | 36 kW |

| Cycle time: | ~4 min. |

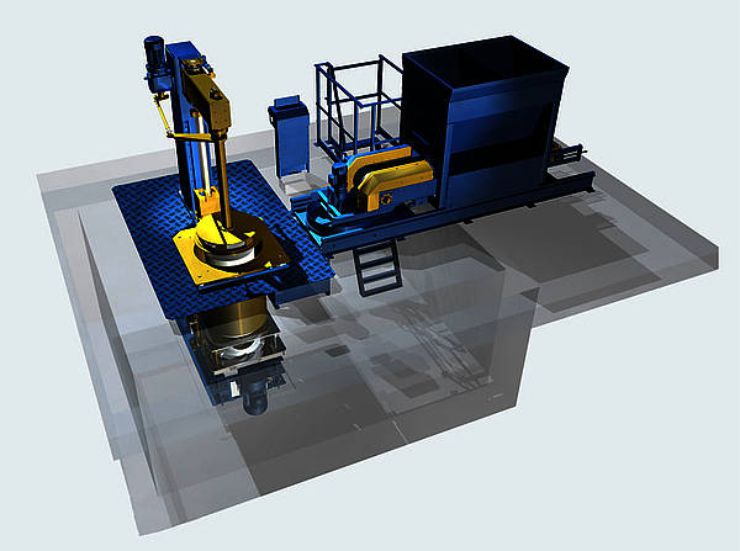

The hydraulic stationary RING-600 machine is designed for the production of concrete pipes, round or with a flange, of the core diameter from fi 300 to fi 600.

The machine comprises:

A mechanical concrete mass fill, streamlining the production process, and a scraper ensures even distribution of the concrete mass in the mold. Hydraulic top ring pressure ensures high quality connections.

The machine construction ensures quick and easy exchange of molds.

The machine uses a special axial vibrator construction, which allows for a very good final product.

Control is done manually using a proportional hydraulic manifold.

Ready-made items are seasoned on steel bottom sleepers. The hand truck is used to haul items to the place of seasoning.

| Operation of the machine: | 1 person |

| Minimum height of the mould: | 1000 mm |

| Maximum core diameter: | 600 mm |

| Minimum core diameter: | 300 mm |

| Maximum the diameter of the coat: | 800 mm |

| Capacity of the batch basket: | 1,2 m3 |

| Capacity of oil container: | 225 l |

| Installed power: | 36 kW |

| Cycle time: | ~4 min. |